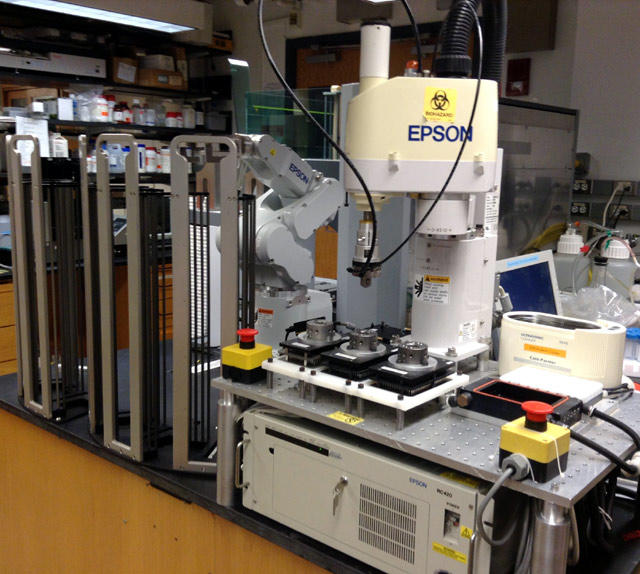

ICCB-Longwood utilizes two different robotic platforms to conduct pin transfer of nanoliter volumes from compound storage plates into assay plates using stainless steel pin arrays (made by V&P Scientific).

- 96- and 384-well pin arrays

- Transfer compounds into 96-, 384- and 1536-well microplates

- 384-well assay plate volume 30 uL - calibrated to transfer 33 nL, 100 nL or 300 nL

- 384-well assay plate volume 10 uL - calibrated to transfer 33 nL or 100 nL

- The standard transfer volume for chemical screens in 384-well is 100 nL.

- 96-well assay plate volume 150 uL - calibrated to transfer 200 nL, 250 nL or 300 nL

Pin Arrays & Calibration provides more information on the pin arrays, the calibration process and selecting the appropriate pin array for your screen.